It’s difficult to think of any aspect of modern life where computers have not made an impact. They’ve changed how we work, how we communicate, the way we conduct business – they’ve even changed how we learn in the classroom.

One area where computers have made the biggest impact is in the design and manufacturing process. Computer Aided Design (CAD) software is used at the initial design stage allowing designers and engineers to create 2D or 3D graphical representations of physical objects. These can then be manufactured through the use of computer aided manufacturing (CAM) software. This facilitates the actual manufacturing of goods by controlling machinery and automating the whole process.

One of the most advanced uses for technology in manufacturing is Computer Numerical Control (CNC), a programme that controls tools and machinery. CNC software is used across many industries; streamlining costs and enhancing productivity.

Here are some of the most commonly used tools controlled by CNC software:

Drills

CNC machine drills are controlled by a platform which can dictate the position of the cut, as well as the depth of the hole being drilled. These are often used in manufacturing processes that require repeated drilling or tapping cycles.

Lathes

A lathe is a machine tool which rotates the work piece on its axis to perform various operations such as: cutting, sanding, knurling, drilling, or deformation. CNC lathes are commonly used to produce camshafts and crankshafts.

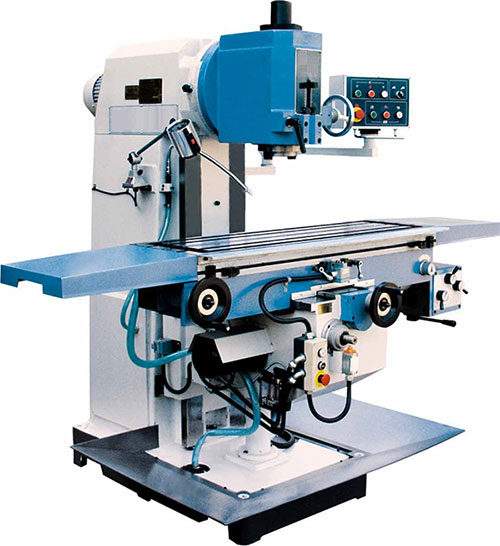

Milling machines

A milling machine removes metal by rotating a multi-toothed cutter that is fed into the moving work piece. The spindle can be fed up and down with a quill feed lever on the head. The use of CNC software gives these machines enhanced precision and accuracy.

Laser cutting machines

Laser cutting is a precise method of cutting a design from a given material using a CAD file to guide it. Again CNC software gives much better accuracy due to the precision of computer controlled cutting.

Plasma cutting machines

Plasma cutting is a process that is used to cut steel and other metals of different thicknesses using a plasma torch. CNC plasma cutters do this under the direction of a software programme where a computerised torch head slices a work piece along the axes of a CNC table.